Converting wood into textile in a non-harmful way

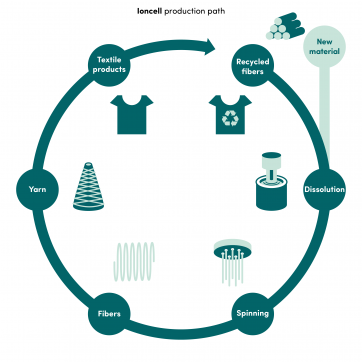

Ioncell-F is a technology developed at Aalto University in collaboration with the University of Helsinki that converts wood and other cellulosic materials into textiles without any harmful chemicals.

The reasoning for new textile materials comes from the fact that the demand of man-made cellulosic fibers (MMCF) exceeds supply by 10-20 million tons in 2030. The market size of these fibers has an annual growth of 6 % corresponding to a value over 700 M€ annually.

The Ioncell-F technology comprises a new environmentally friendly and safe method to produce high quality MMCF for textiles and special applications (nonwovens, composites). It is based on unique technology utilizing novel tailor-made ionic liquid.

The technology is bio-based and besides, an environmentally friendly alternative to the highly water-intensive cotton production. The technology may revolutionize the recycling of textile waste. The target of this project is to develop the new sustainable processing concept for manufacturing these man-made cellulosic fibers towards commercialization by creating symbiotic relationships between interested industries and stakeholders. The project focuses on the business model development to support the commercialization of Ioncell-F technology.

Ioncell-F has a solid business potential but it needed to formulate a business and incubation model for commercialization purposes, which is the main target of the project with EIT Climate-KIC. Ioncell-F team arranged a targeted workshop for stakeholders and investors. Based on the information from this workshop, a preliminary commercialization, business and venture model was formulated.

As a significant result of this project, a large funding proposal “Ioncell-F, a novel man-made cellulosic fiber” for Finnish Funding Agency for Technology and Innovation Tekes was constructed. A funding of 851,263 euros was granted in May 2017 to this project parallel to another research grant of 1.5 M€ from Tekes dealing with the same process.

Impact

Demand for textile fibers is rapidly increasing because of the population growth and an improved standard of living. The future demand for textiles cannot be met by increasing the production of cotton due to the large land area required for farming and the amount of water required for irrigation. Therefore, sustainable man-made fibers are needed to substitute cotton.

Currently, there are two main man-made cellulose fibers (MMCF) on the market: viscose and lyocell (Tencel®). Production of viscose requires the use of carbon disulfide, a very toxic chemical. The solvent applied in the production of Tencel® fibers, NMMO, also has an intrinsic shortcoming: its chemical and thermal instability, causing a risk of dangerous runaway reactions.

In Ioncell-F technology, the environmental impacts must be emphasized. As to solvents used, the technology is almost closed-loop. The water use with Ioncell-F, for example, is less than 500 liter per kilogram of fiber whereas the corresponding figure for cotton is more than 10000. Moreover, the traditional process viscose fibers uses hazardous carbon disulfide to dissolve cellulose and generates a wide spectrum of toxic sulfurous side products while our process does not produce any harmful waste streams or high volumes.

As to legal aspects, climate change mitigation sets eventually boundaries to the growth of using synthetic petroleum-based fibers that account for about half of the present fiber usage. Additional pressure to petroleum- based fibers come from the increasing awareness and need to reduce microplastics.